23

2024

-

06

A Guide to EPDM Gaskets in the Chemical Industry

Introduction

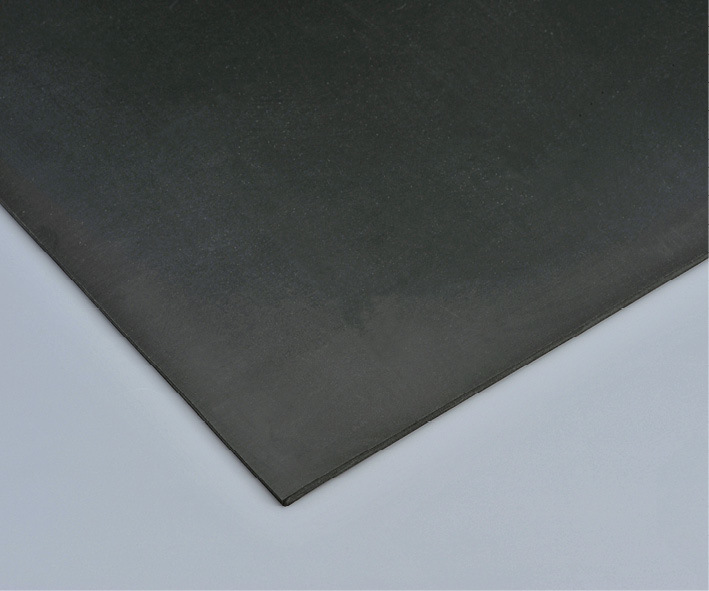

EPDM (ethylene propylene diene monomer) gaskets play a crucial role in the chemical industry, especially in the realm of rubber products. These gaskets are known for their excellent resistance to heat, ozone, weather, and aging, making them a popular choice for sealing applications in various chemical processing plants.

One key property of EPDM gaskets is their ability to withstand a wide range of temperatures, from -50°C to 150°C, without compromising their performance. This makes them suitable for use in both high and low-temperature environments, providing reliable sealing solutions for chemical processing equipment.

EPDM gaskets are also highly resistant to a variety of chemical substances, including acids, alkalis, and solvents. This chemical resistance ensures that the gaskets maintain their integrity and effectiveness even when exposed to harsh industrial chemicals, prolonging their service life and reducing the need for frequent replacements.

In addition to their excellent physical and chemical properties, EPDM gaskets are also known for their flexibility and durability. They can easily conform to irregular surfaces, ensuring a tight seal and preventing leaks in chemical processing equipment. Their resilience to compression set and deformation further enhances their sealing performance, making them a reliable choice for critical applications in the chemical industry.

Overall, EPDM gaskets are essential components in the chemical industry, providing reliable sealing solutions for a wide range of applications. Their unique combination of properties, including temperature resistance, chemical resistance, flexibility, and durability, makes them an ideal choice for sealing sensitive equipment in chemical processing plants.

More News