Categories

Encapsulated O-Rings

Category:

O-Rings/Seal Ring

- Product Description

-

- Commodity name: Encapsulated O-Rings

- Commodity ID: PC-0031

PFA Encapsulated O-Rings FEP Encapsulated O-Rings FEP/PFA Encapsulated Silicone O-Rings

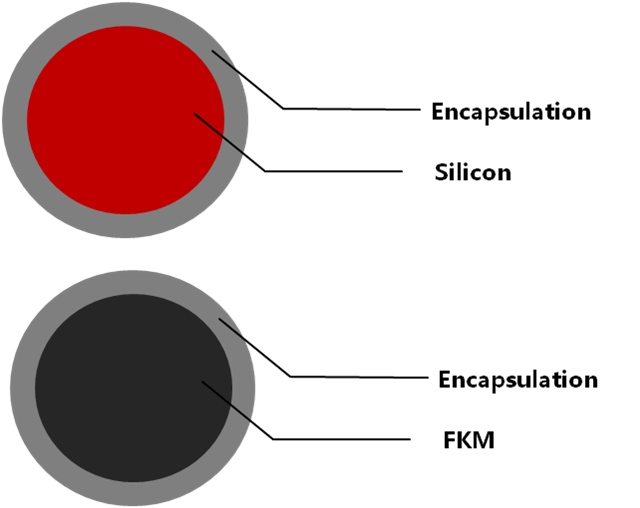

FEP-/PFA-encapsulated O-rings consist of an elastomer core and a seamlessly closed casing of modified PTFE. The elastomer core made of FKM (Viton) or VMQ (silicone) guarantees an even pretensioning at the sealing point. The seamless casing is composed of FEP (fluorinated ethylene propylene) or PFA (perfluoroalkoxy-copolymer). It ensures reliable sealing and high resistance to aggressive media.

This produces performance similar to that of a PTFE material. Encapsulated O-rings are exclusively used in static applications since movement or abrasive media can destroy the casing.

■.FEP-/PFA-encapsulated O-rings Materials:

1.FKM or silicone is used as the material for the core of the encapsulated O-ring.

2.EPDM is not recommended due to heat-related changes during the manufacturing process. FKM and silicone withstand these temperatures during production without a decline in performance.

3.FKM core – FKM (black) features very good rubber-elastic qualities. FKM has the capacity to re-assume its original form after its deformation thanks to its outstanding compression set.

4.Silicone core – The silicone core (mostly red) is considerably softer than an FKM core. In turn, it is more temperatureresistant. In addition to its superb thermal resistance, it has very good cold flexibility.

5.FEP encapsulation – FEP (fluorinated ethylene propylene) gives an O-ring its tremendous characteristics relating to its resistance to nearly all liquids, gases and chemicals. The exceptions are liquid alkali metals and some fluorine compounds.

6.PFA encapsulation – Perfluoroalkoxy copolymer (PFA) resembles FEP in its areas of application. It is distinguished by improved cold flow properties and optimized mechanical qualities at higher temperatures.■.FEP-/PFA-encapsulated O-rings profile:

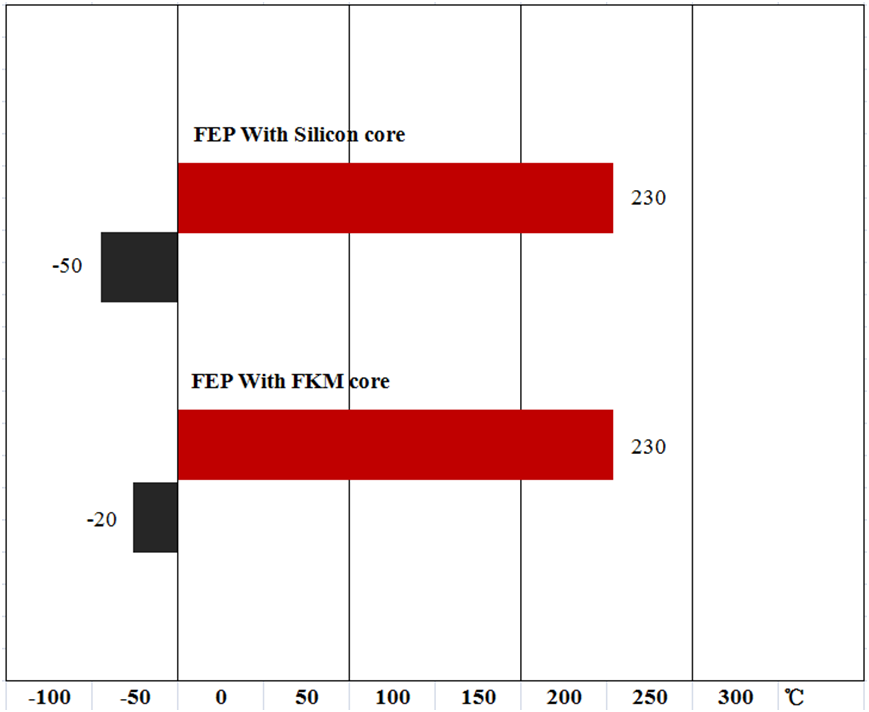

■.FEP encapsulated O-rings Temperature Range:

• -50°C to +230°C with Silicone core.

• -20°C to +230°C with FKM core.

■.FEP Encapsulated o-ring Gas permeability:

FEP/PFA encapsulations have a much lower gas permeation rate than most other plastics. Highly corrosive gases usually don’t chemically attack the FEP/PFA encapsulation, but may eventually permeate through and damage the elastomer core.

In general, permeation increases with temperature, pressure,and surface contact area and decreases with increased film thickness.■.FEP Encapsulated o-ring applications :

• Access covers

• Autoclaves

• Cartridge filters

• Chemical reactor vessels

• Cryogenics

• Gas compressors

• Heat exchangers

• Hose couplings

• Mechanical seals

• Pipelines

• Pressure vessels

• Pumps and valves※For more information on FEP Encapsulated o-rings please contact 91视频H污污 seals

Previous

Next

Previous

Next

MESSAGE