13

2023

-

12

The value of silicone o-ring seals

Summary

Silicone o-rings are distinguished by their temperature resilience, resistance to weather conditions, and bio-inert characteristics, which make them ideal for various applications.

Despite the existence of other materials like Nitrile, Viton, and EPDM, silicone o-rings excel in numerous sectors, including food and beverage, medical, electronics, and automotive due to their unique properties.

The field continues to evolve with the development of liquid silicone rubber (LSR) and the use of material fillers, which has led to market growth and increased demand in various industries.

Introduction

In industrial equipment, the o-ring is a silent, steadfast workhorse. Its simplicity equates to its genius; a loop of elastomer with a round cross-section, designed to be seated in a groove and compressed during assembly to form a seal. The simple o-ring is an integral part of the industrial machinery, facilitating the smooth running of everyday life as we know it. Among the vast array of o-ring materials available, silicone o-rings hold a special place due to their unique properties.

Silicone o-rings are known for their impressive range of temperature compatibility, excellent resistance to various external factors, and flexibility. But just like any material, they come with their own set of limitations. In this comprehensive guide, we delve into the nuances of silicone o-rings—their advantages, disadvantages, and applications. Additionally, we’ll explore how silicone stands against other popular o-ring materials and share some invaluable tips for selection and maintenance.

History of Silicone O-Rings

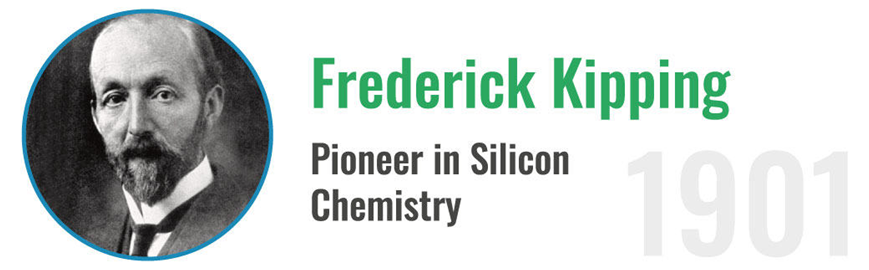

Like many other industrial products, silicone o-rings have a rich history rooted in the rapid growth of technology and innovation during the 20th century.

- Discovery of Silicone: In 1901, Frederick Kipping developed the first silicone polymers, laying the groundwork for silicone o-rings.

- Mass Production: Silicone was refined and mass-produced during World War II to meet the aircraft industry`s needs for a material resistant to extreme temperatures.

- Commercial Expansion: Post-war, commercial applications of silicone grew rapidly, especially in the sealing industry.

- Silicone Rubber Development: The 1960s saw the creation of silicone rubber, opening new avenues for o-ring usage thanks to its unique properties, such as temperature stability, flexibility, and biocompatibility.

- Rise of Silicone O-Rings: Due to increasing industrialization post-war, the demand for reliable sealing solutions surged, leading to the widespread adoption of silicone o-rings in various industries.

- Modern Improvements: Today, with advancements in technology and manufacturing, silicone o-rings are produced in various sizes and hardness values, tailored for specific applications.

The story of silicone o-rings is a testament to the power of innovation and adaptation. They have become an essential component in industries worldwide since their modest beginnings. As technology continues to evolve, so will the role of silicone o-rings, securing their place in the annals of industrial history.

The Pros of Silicone O-Rings

- Wide Temperature Range: Silicone o-rings can operate in temperatures as low as -60 degrees Celsius and as high as 225 degrees Celsius or -76 degrees Fahrenheit to 437 degrees Fahrenheit, making them a versatile choice for industries with machinery operating in extreme temperature conditions.

- Exceptional Resistance: These o-rings boast excellent resistance to weathering, ozone, and UV rays. They maintain their flexibility and sealing abilities in various environmental conditions, making them ideal for outdoor applications.

- Bio-inert Nature: Silicone o-rings are non-reactive with biological materials, making them suitable for the food and beverage industries, where they often come into contact with edible items and ensure no harmful chemicals leach into the food.

- Medical Applications: The bio-inert property of silicone o-rings also extends to medical applications, where they are used in various types of equipment. Their non-reactivity ensures safety and reliability in sealing medical devices and facilitating fluid transfer.

- Electrical Insulation: Known for their electrical insulating properties, silicone o-rings can effectively resist electricity, making them ideal for electrical and electronic equipment use. This property, along with silicone’s thermal stability, makes these o-rings perfect for electrical insulation applications.

Silicone vs. Other Materials

When choosing an o-ring, it’s essential to consider the operating environment and the specific demands of your application. Comparing silicone to other materials such as Nitrile, Viton (FKM), and EPDM can help you make a more informed decision.

Nitrile o-rings, for example, are known for their excellent resistance to petroleum-based oils and fuels, a property that silicone lacks. They also possess superior abrasion resistance compared to silicone. However, Nitrile doesn’t match silicone regarding temperature extremes and weather resistance.

Viton (FKM) o-rings are another popular choice. They are noted for their resistance to chemicals and high temperatures, surpassing silicone in certain aspects. However, FKM o-rings can’t match silicone’s flexibility at low temperatures or its electrically insulating properties.

EPDM o-rings provide excellent resistance to weather, ozone, UV rays, and certain chemicals. In these aspects, they are comparable to silicone. However, EPDM doesn’t perform as well with petroleum-based oils and is generally less suitable for food or medical applications than silicone.

In essence, each o-ring material has its strengths and weaknesses, and there are scenarios where silicone outperforms others and vice versa. Thus, it’s crucial to consider the specific needs of your application when selecting the o-ring material.

For more information on the dimensions, materials, product catalog and prices of silicon o-ring seals, please contact us below

Contact: Emily Ke

Email: Emilyke@lanhechina.com

Tel: (86)769-85637586

Phone: (86) 138 2927 2978

More News