Categories

Flame Retardant Rubber

Category:

Rubber Parts

- Product Description

-

- Commodity name: Flame Retardant Rubber

- Commodity ID: PCA-005

Flame retardant rubber refers to the rubber with flame retardant and flame retardant. Rubber is an organic flammable material that endangers safety, so all kinds of rubber products, such as mine rubber conveyor belt and vehicles and ships, are required to have inflammability and flame retardant properties. Flame retardant rubber are: chloroprene rubber, chlorosulfonated polyethylene, polyvinyl chloride and silicone rubber. Flame retardancy can be improved by combining a refractory polymer with flammable rubber, such as polyvinyl chloride with nitrile butadiene rubber. Increasing the crosslinking density of vulcanizates can also improve the fire resistance. Adding flame retardants is a way to improve the flammability of rubber. Commonly used flame retardants are: chlorinated paraffin and antimony trioxide phase combination, aluminum hydroxide, sodium borate, molybdenum oxide and tritoluene phosphate, etc. Clay or white carbon black should be used in the filler.

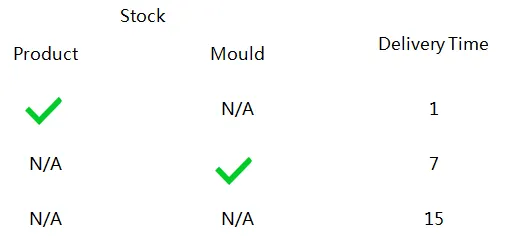

Item: Medical rubber bottle stopper Material: NR, IIR, SBR Certificate: IATF 16949:2016 / ISO 9001:2015 / ISO 45001:2018 / ISO 14001:2015 /REACH/ROHS/MSDS/LFGB/FDA/NSF/WRAS/KTW/DVGW Drawing Format: .stp / .step / .igs /.stl /.dwg / .pdf Parameters: Inch, centimeter, millimeter, etc. Function: Industrial parts /daily supply / Automotive/ Medical device, Food,Drinking water,Beverage industry,etc... Mold Material: No. 50 steel, No. 45 steel, P20, 8407, H13, 718H, etc. Mold Precision: If no special request, apply to ISO3302:2014 standards, class 2. Mold Life-cycle: 100,000-500,000 shots. Packing: Pack in bulk / poly bag / bubble bag / color box. Sample: Available. One cavity sample mold Price Tip: final actual price depends on your design, material request, surface treatment, order qty, package request, etc. Delivery time:

Certification:

Keywords:

Keywords:- Rubber Parts

Previous

Previous

MESSAGE