Categories

Buna-N(NBR/Nitrile )O-rings

Category:

O-Rings/Seal Ring

- Product Description

-

- Commodity name: Buna-N(NBR/Nitrile )O-rings

- Commodity ID: LH2023-01

Nitrile rubber O-rings NBR O-ring Buna-N oring Buna Nitrile O-rings Buna-N NBR Seals NBR O-ring 70 Shore A Metric Nitrile (NBR) O-rings

Nitrile rubber O-rings often referred to as Buna-N oring seals&NBR O-rings

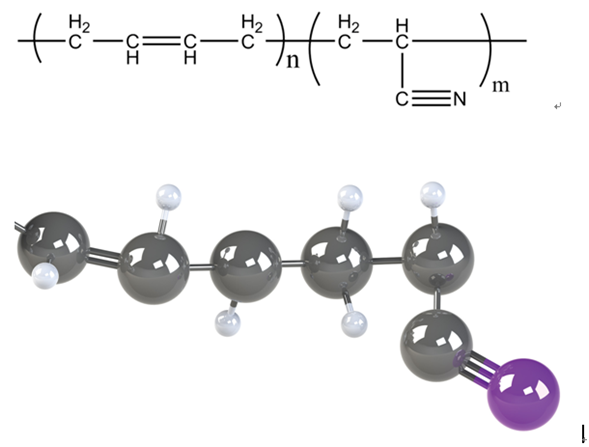

The most commonly used elastomer in the seals industry and is a copolymer of two monomers; acrylonitrile (ACN) and butadiene.

The properties of this elastomer are ruled by the ACN content which is broken down into three classifications:

? High Nitrile: >45% ACN content

? Medium Nitrile: 30 – 45% ACN content

? Low Nitrile: <30% ACN content

It is the best rubber material with oil resistance, usually used to make sealing rings, oil seals, gasket,washer and is widely used in various sealing industries.■.Properties of NBR Buna-N (Nitrile &Buna-N) Rubber:

Hardness, Shore A:50 - 90

Tensile strength:500- 2500 PSI

Elongation at break %:600% maximum

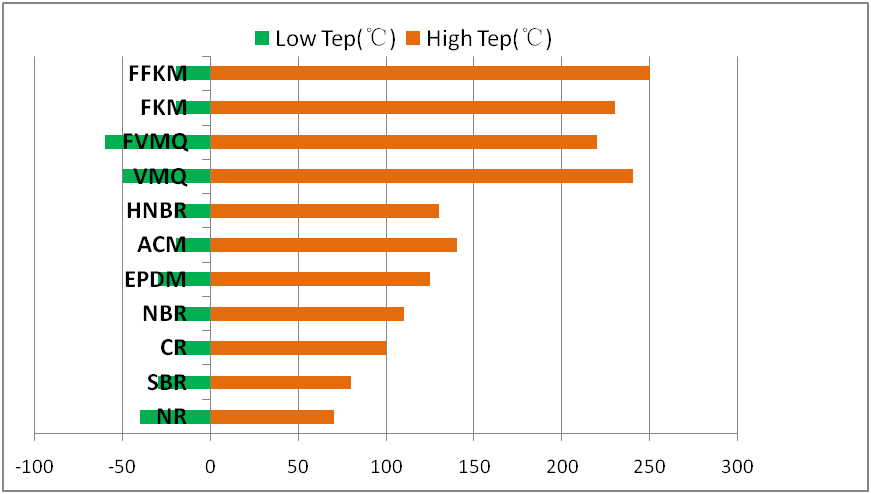

Density:Can becompounded around 1.0g/cm3■.NBR O-ringsTemperature Range:

Standard Low Temperature:-25℃(-13℉)

Standard High Temperature: -120℃(248℉)

※The temperature range is the reference value of the typical compounds, the value is different according to the material formulation, please consult the

LanHe Seals engineering and technology Department for details

■.NBR O-rings Cure system:

1.Sulfur-Cured

Standard Nitrile o-rings are usually sulfur-cured.Sulfur-cured compounds

offer better low-temperature properties but are more prone to hardening

with high temperatures.2. Peroxide-Cured

Peroxide-cured nitrile o-rings have better heat resistance and lower compression

sets but are more expensive and more difficult to process.■.NBR O-rings Hardness range:70~ 90 Shore A (N70&N80 &N90)

※The most widely used and most in stock in LanHe Seals is the standard hardness of 70 Shore A■.Molecular formula of NBR rubber material:

■.NBR O-rings advantage:

1. Durability

Nitrile rubber is highly durable and can withstand harsh environmental conditions, including exposure to chemicals and oils. Its ability to resist wear and tear makes it suitable for use in applications that require long-term performance.2. Oil and Fuel Resistance

Nitrile rubber is highly resistant to oils and fuels, making it an ideal choice for applications in the automotive,oil and gas, and manufacturing industries. Its resistance to these substances ensures that it can provide reliable performance even in environments with high exposure to oils and fuels3.Cost-Effectiveness

Nitrile rubber is a cost-effective material that offers numerous benefits and can provide efficient solutions for various industrial applications. Its versatility and durability make it a popular choice for manufacturers looking for cost-effective solutions without compromising on quality.■.NBR O-rings dimensions:

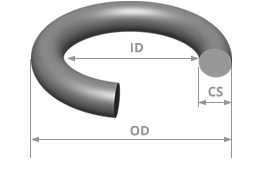

CODE1: CS--Cross Section

CODE2: ID--Inside Diameter

CODE3: OD--Outside Diameter OD=ID+CS*2 Length = (ID + CS) * π

■.Size chart for the O-rings implemented by 91视频H污污 seals:

1. ISO3601 Mestric O-rings

2. JIS B 2401 Metric O-rings

3. BS 1806 Metric O-rings

4. AS-568O-rings

5. Parker 5-XXX Series O-rings

6. Parker 2-XXX Series O-rings

7. ISO6149 Metric O-rings

8. DIN 371 Metric O-rings

9. NF-T 47-5001 Metric O-rings

10. BS 4518 Metric O-rings

11. SMS 1586 Metric O-rings

12. GB/T 3452.2-2018 rubber O-rings※For more information on rubber o-ring product please contact 91视频H污污 seals

Keywords:- NBR O-Ring

- Buna-N oring

- Nitrile rubber O-Rings

Previous

Next

Previous

Next

MESSAGE