Categories

Silicone rubber seal diaphragm

Category:

Rubber Parts

- Product Description

-

- Commodity name: Silicone rubber seal diaphragm

- Commodity ID: PCA-013

Rubber diaphragm seal; rubber membrane, also known as rubber film sealing products, rubber diaphragm. It is a sheet rubber product.Rubber solenoid pneumatic pump diaphragm valve.Consisting of single or multiple layers of fabric coated on both sides, or pure glue without fabric. According to the structure, it can be divided into plane diaphragm, corrugated diaphragm, disc diaphragm and rolling diaphragm. According to the principle of action, it can be divided into isolation diaphragm, penetration diaphragm and motion diaphragm. According to the use conditions can choose different fabric and rubber material manufacturing, commonly used NBR, PU, NBR/ polysulfide rubber and rubber material, also useful silicone rubber, fluorine rubber and chloroether rubber. The rubber diaphragm shall have the advantages of heat resistance, medium resistance, pressure resistance, flexure resistance and high sensitivity. The manufacturing method is to glue coated fabric and glue material after cutting and laminating molding with film vulcanization, flat film can also be used drum vulcanization machine continuous vulcanization after punching. Rubber diaphragm is widely used in industry, transportation and other sectors, can be used as instruments, regulators and other automatic control system sensitive elements. The working temperature is generally -50 ~ +100 ℃, and the working pressure is 0 ~ 2bar.

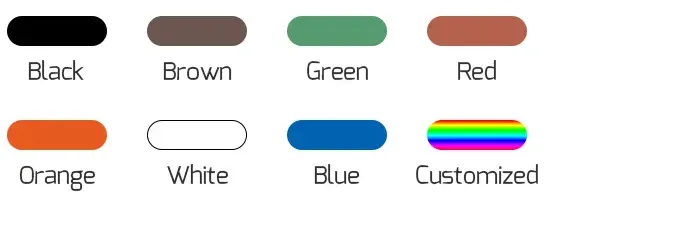

Item: Silicone rubber seal diaphragm Material: EPDM, NBR, SBR, NR, Silicone(VMQ), Neoprene(CR), HNBR, XNBR, FKM, FFKM, FVMQ, FLAS, PTFE, PU, ECO, IIR, ACR, etc… Certificate: IATF 16949:2016 / ISO 9001:2015 / ISO 45001:2018 / ISO 14001:2015 /REACH/ROHS/MSDS/LFGB/FDA/NSF/WRAS/KTW/DVGW Drawing Format: .stp / .step / .igs /.stl /.dwg / .pdf Parameters: Inch, centimeter, millimeter, etc. Function: Industrial parts /daily supply / Automotive/ Medical device, Food,Drinking water,Beverage industry,etc… Mold Material: No. 50 steel, No. 45 steel, P20, 8407, H13, 718H, etc. Mold Precision: If no special request, apply to ISO3302:2014 standards, class 2. Mold Life-cycle: 100,000-500,000 shots. Packing: Pack in bulk / poly bag / bubble bag / color box. Sample: Available. One cavity sample mold Material color table:

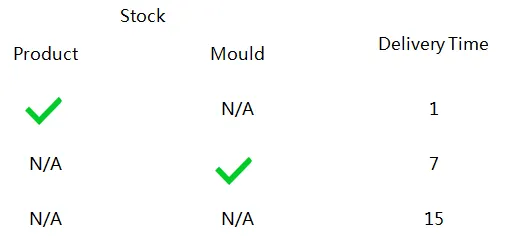

Delivery time:

Certification:

Keywords:

Keywords:- Rubber Parts

Next

Next

MESSAGE