Categories

V ring Seals

Category:

Oil Seal

- Product Description

-

- Commodity name: V ring Seals

- Commodity ID: PC-0061

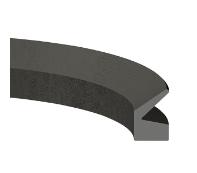

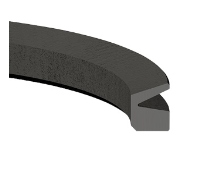

Rubber V-seal V Ring VA VS VL V-Rings & V-Seals V Ring Seals & Bearing Deflector Seals V-Rings in Viton?, FKM Meterial: NBR FKM Application: Pump Valve Speed: 0-30m / s lip: Lip Seal Shape: V-Type Pressure: Pressure type Working Medium: Water, oil, grease, dust and so on;

V-Rings & V-Seals:

V-ring seals provide effective protection against dry and wet contamination.

The V-ring also reduces wear and extends the service life of the oil seal and bearings.

The V-ring also performs well in dry running applications. Because it is all rubber and very elastic,

it can be stretched over flanges or other components for easy installation with very little dis-assembly.

The function of a V-seal is to exclude dirt, water or other aggressive media from entering bearing housings while also retaining grease.

The V-seal stretches over the shaft and assumes a tight interference fit.

The V-seal rotates with the shaft causing the lip to rotate against the housing or bearing.As the speed increases, friction decreases due to centripetal force.

■.V-Rings & V-Seals advantages:

1.Pure elastic rubber construction without any additions of metals

2.Eases the workload on design processes and easily installed with no remachi-ning needed

3.Eliminates the need for re-machining of the axle surface and complies with the surface precision and hardness for the axle surface. Therefore axles do not necessarily need to be hard.

4.Easy installation and removal; high reliability

5.Small surface contact with other parts, thereby lowering frictional forces and heating due to friction resulting in a longer life span

■.V-Rings & V-Seals Temperature Range(Depending on the rubber material chosen, there are usually different temperature ranges)

Standard Low Temperature:-25℃(-13℉)

Standard High Temperature: -250℃(482℉)■.V-Rings & V-Seals Hardness range:50~ 90 Shore A (70 Shore A is the most common)

■.V-Rings & V-Seals types:

VA Types:Due to the very wide cross section and wide diameter range, VA Type is the most common V-seal design.

VS Types:The VS Type features a larger I.D. contact area than the VA - style. The added contact with the shaft surface provides extra torque to the sealing lip.

VL Types:The VL-style incorporates a very thin cross-section and is used primarily where there are space limitations.

■. V-Rings & V-Seals dimensions:

NO. Φ诲1 Φ诲 B C A ΦD2 MAX NO. Φ诲1 Φ诲 B C A ΦD2 MAX VS001 4.5-5.5 4 5.2 2 3.9 d1+1.0 VS021 53.0-58.0 49 13 5 9.5 d1+3.0 VS002 5.5-6.5 5 5.2 2 3.9 d1+1.0 VS022 58.0-63.0 54 13 5 9.5 d1+3.0 VS003 6.5-8.0 6 5.2 2 3.9 d1+1.0 VS023 63.0-68.0 58 13 5 9.5 d1+3.0 VS004 8.0-9.5 7 5.2 2 3.9 d1+1.0 VS024 68.0-73.0 63 15.5 6 11.3 d1+4.0 VS005 9.5-11.5 9 5.2 2 3.9 d1+1.0 VS025 73.0-78.0 67 15.5 6 11.3 d1+4.0 VS006 11.5-13.5 10.5 5.2 2 3.9 d1+1.0 VS026 78.0-83.0 72 15.5 6 11.3 d1+4.0 VS007 13.5-15.5 12.5 7.7 3 5.6 d1+2.0 VS027 83.0-88.0 76 15.5 6 11.3 d1+4.0 VS008 15.5-17.5 14 7.7 3 5.6 d1+2.0 VS028 88.0-93.0 81 15.5 6 11.3 d1+4.0 VS009 17.5-19.0 16 7.7 3 5.6 d1+2.0 VS029 93.0-98.0 85 15.5 6 11.3 d1+4.0 VS010 19.0-21.0 18 10.5 4 7.9 d1+3.0 VS030 98.0-105.0 90 15.5 6 11.3 d1+4.0 VS011 21.0-24.0 20 10.5 4 7.9 d1+3.0 VS031 105.0-115.0 99 18 7 13.1 d1+4.0 VS012 24.0-27.0 22 10.5 4 7.9 d1+3.0 VS032 115.0-125.0 108 18 7 13.1 d1+4.0 VS013 27.0-29.0 25 10.5 4 7.9 d1+3.0 VS033 125.0-135.0 117 18 7 13.1 d1+4.0 VS014 29.0-31.0 27 10.5 4 7.9 d1+3.0 VS034 135.0-145.0 126 18 7 13.1 d1+4.0 VS015 31.0-33.0 29 10.5 4 7.9 d1+3.0 VS035 145.0-155.0 135 18 7 13.1 d1+4.0 VS016 33.0-36.0 31 10.5 4 7.9 d1+3.0 VS036 155.0-165.0 144 20.5 8 15 d1+5.0 VS017 36.0-38.0 34 10.5 4 7.9 d1+3.0 VS037 165.0-175.0 153 20.5 8 15 d1+5.0 VS018 38.0-43.0 36 13 5 9.5 d1+3.0 VS038 175.0-185.0 162 20.5 8 15 d1+5.0 VS019 43.0-48.0 40 13 5 9.5 d1+3.0 VS039 185.0-195.0 171 20.5 8 15 d1+5.0 VS020 48.0-53.0 45 13 5 9.5 d1+3.0 VS040 195.0-210.0 180 20.5 8 15 d1+5.0

Previous

Next

Previous

Next

MESSAGE