Categories

Perfluoroelastomer (FFKM) O-rings

Category:

O-Rings/Seal Ring

- Product Description

-

- Commodity name: Perfluoroelastomer (FFKM) O-rings

- Commodity ID: LANHE2302

FFKM O-rings & seals Perfluoroelastomer FFKM O-rings High Temperature O-rings FFKM O-rings & viton FFKM Perfluoroelastomer Metric O-rings Perfluoroelastomer (FFKM) Material for O-rings

Perfluoroelastomer FFKM O-rings

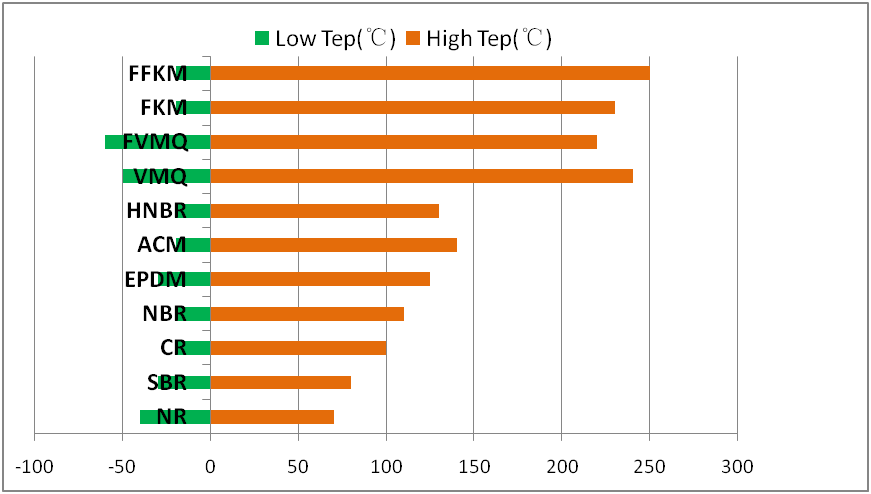

Static seals made of Perfluoroelastomer rubber(FFKM) for use in harsh conditions where fluororrubbers(FKM) are not suitable. The O-rings are elastic and thermologically and chemically stable. Long-term operating temperature -25℃~250℃ , short-term up to 300℃, below the embrittlement temperature still has a certain plasticity, hard but not brittle, flexible. Stable for all chemicals except swelling in fluorinated solvents. Commonly used in aerospace, aviation, chemical, petroleum, nuclear energy and other industrial sectors.

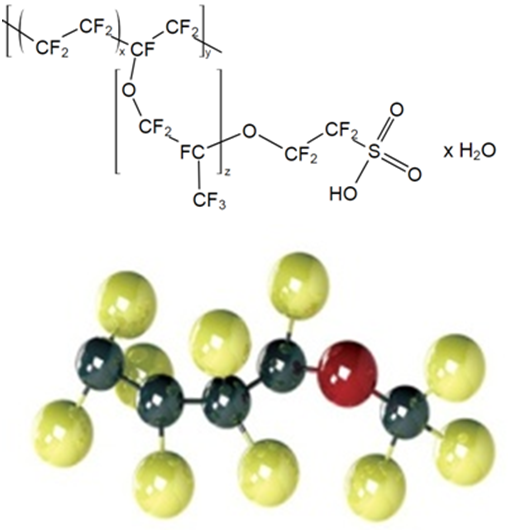

■.Material description:Perfluorinated rubber refers to the terpolymer of perfluorinated (methyl vinyl) ether, tetrafluoroethylene and perfluoroethylene ether. Also known as perfluoroether rubber.Perfluorinated rubber has very high strength and chemical stability, it is the best rubber material with high temperature resistance, good thermal aging performance, strong oil resistance, cold shrinkage resistance, aging resistance and fatigue resistance. Perfluoroelastomer (FFKM) rubber products have good physical and mechanical properties, good insulation properties and water resistance.■.Properties of Perfluoroelastomer FFKM Rubber O-rings:Tensile strength:1700- 3000 PSIElongation at break %:100~300%Density:1.9-2.5g/cm3■.FFKM Rubber O-rings Temperature Range:Standard Low Temperature:-25℃(-13℉)Standard High Temperature: -250℃(482℉)※The temperature range is the reference value of the typical compounds, the value is different according to the material formulation, ■. FFKM Rubber O-rings Hardness range:50~ 90 Shore A (70 Shore A is the most common)■.FFKM Rubber O-rings Cure system:At present, perfluorinated rubber has several crosslinking agents, some of the more common crosslinking agents are free radical co-vulcanization agents, catalytically triggered triazine vulcanization agents to form benzooxazole crosslinking bonds. These methods can fully vulcanize their respective perfluorinated rubbers, however, they have their own unique advantages and disadvantages. The user should carefully select the appropriate curing agent to meet the final use requirements. In general, in order to maximize the performance of each vulcanization system, secondary vulcanization is required.Peroxide crosslinkers are mostly used for chemical resistant PEF grades. Free radicals produced by combining peroxides with bromine or iodine-containing cure point monomers (X-CSMA:X=Br or I) and suitable co-crosslinkers are ideal for use at temperatures up to 230 ° C and in vapor, acid and hot water environments. The permanent deformation of perfluorinated rubber cured by X-CSM and peroxide vulcanizing agent at high temperature is not as good as that cured by triazine vulcanizing systemWhen crosslinking chemically resistant perfluorinated rubber, triallyl isocyanate (TAIC) as an assistant crosslinking agent shows excellent comprehensive properties in terms of physical properties and heat resistance. Taics can migrate from mixed polymers and tend to copolymerize in cross-linking reactions. Therefore, it affects the processability of the polymer (for example, contaminating the mold), so trimethyl urea isocyanate (TMAIC) is sometimes used instead of TAIC. Compression permanent deformation performance can be improved by using TMAIC or TAIC. This method slightly delays vulcanization, resulting in a more ordered cross-linked structure during the cross-linking process■. Molecular formula of FFKM rubber material:

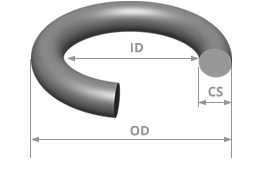

■. FFKM Rubber O-rings Hardness range:50~ 90 Shore A (70 Shore A is the most common)■.FFKM Rubber O-rings Cure system:At present, perfluorinated rubber has several crosslinking agents, some of the more common crosslinking agents are free radical co-vulcanization agents, catalytically triggered triazine vulcanization agents to form benzooxazole crosslinking bonds. These methods can fully vulcanize their respective perfluorinated rubbers, however, they have their own unique advantages and disadvantages. The user should carefully select the appropriate curing agent to meet the final use requirements. In general, in order to maximize the performance of each vulcanization system, secondary vulcanization is required.Peroxide crosslinkers are mostly used for chemical resistant PEF grades. Free radicals produced by combining peroxides with bromine or iodine-containing cure point monomers (X-CSMA:X=Br or I) and suitable co-crosslinkers are ideal for use at temperatures up to 230 ° C and in vapor, acid and hot water environments. The permanent deformation of perfluorinated rubber cured by X-CSM and peroxide vulcanizing agent at high temperature is not as good as that cured by triazine vulcanizing systemWhen crosslinking chemically resistant perfluorinated rubber, triallyl isocyanate (TAIC) as an assistant crosslinking agent shows excellent comprehensive properties in terms of physical properties and heat resistance. Taics can migrate from mixed polymers and tend to copolymerize in cross-linking reactions. Therefore, it affects the processability of the polymer (for example, contaminating the mold), so trimethyl urea isocyanate (TMAIC) is sometimes used instead of TAIC. Compression permanent deformation performance can be improved by using TMAIC or TAIC. This method slightly delays vulcanization, resulting in a more ordered cross-linked structure during the cross-linking process■. Molecular formula of FFKM rubber material: ■. FFKM Rubber O-rings dimensions:CODE1: CS--Cross SectionCODE2: ID--Inside DiameterCODE3: OD--Outside Diameter OD=ID+CS*2 Length = (ID + CS) * π

■. FFKM Rubber O-rings dimensions:CODE1: CS--Cross SectionCODE2: ID--Inside DiameterCODE3: OD--Outside Diameter OD=ID+CS*2 Length = (ID + CS) * π ■. Size chart for the O-ring implemented by 91视频H污污 seals:

■. Size chart for the O-ring implemented by 91视频H污污 seals:

1. ISO3601 Metric O-rings

2. JIS B 2401 Metric O-rings

3. BS 1806 Metric O-rings

4. AS-568 O-rings

5. Parker 5-XXX Series O-rings

6. Parker 2-XXX Series O-rings

7. ISO6149 Metric O-rings

8. DIN 371 Metric O-rings

9. NF-T 47-5001 Metric O-ring

10. BS 4518 Metric O-ring

11. SMS 1586 Metric O-ring

12. GB/T 3452.2-2018 rubber O-ring

※For more information on rubber o-ring product please contact 91视频H污污 seals

Previous

Next

Previous

Next

MESSAGE